CMYK - No Such Colour

We are so far into the digital age yet there is still a bit of confusion about CMYK (and RGB) colour models. I'll do an overview of the CMYK colour model and the affect on digital print it has. The biggest misconception is that a colour specified as CMYK percentages alone represents an actual colour. It would be wrong to accuse a digital printer for producing incorrect colour if the only thing you provided was a combination of CMYK percentages such as those seen in corporate identity manuals. Read on to find out why...

CMYK and RGB are 'device dependent' colour models. This means they do not represent a precise colour unless they are associated to a colour space (for a device), ie. an ICC profile like US Web Coated SWOP v2. Without this association to an ICC profile they are simply numbers representing a percentage of unknown ink. Fortunately most ICC profiles that are loaded into design software (like Adobe Photoshop) have similar hues and densities so colour representation is reasonably similar when flicking between them. This is not the case with digital print because of our diverse inks and media. So for the CMYK colour model to work properly, we have to make sure that we make and maintain accurate output ICC profiles too.

We have inksets from many manufacturers, each with unique properties. One property is the hue, each brand is different and in some cases by quite alot. This means from the same file (CMYK with no ICC profile) we will produce inconsistent colour between inksets. But if you were to create a file and embed the US Web Coated SWOP v2 ICC, we know you are expecting a specific colour ie 100%M 100%Y from that space, then we set that in our software and it will reformulate the percentages to best represent that colour on the printer and substrate it is being processed. This process accounts for the colour and absorbtion of the media too... papers, banners, vinyls and plastics have different white points which affect the colour.

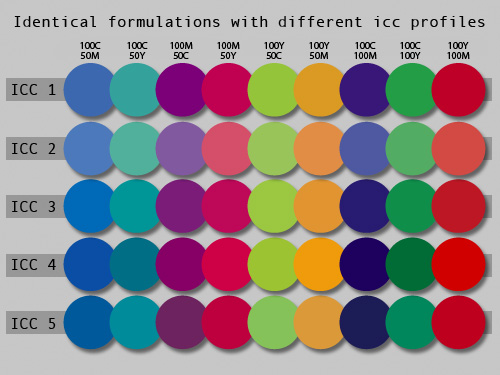

This chart demonstrates how a mix of 5 ICC profiles represent the same CMYK formulations 'as is, uncontrolled'. In a colour managed environment, our software would adjust each of these colours to best match the embedded or specified ICC colour space.

In a perfect world you'd have calibrated your monitor and have that icc set in your computers colour management. In your design programme you'd have colour management turned on and working spaces set. Your computer will best match the colours on your screen to match the icc space set in the design programme. When you provide your file to us we would see that you created your file in a specific colour space and we'd preserve that and set our printers to match it. The colour in your file in a perfect world would be the same on your screen and on the print we provided. Unfortunately there are a whole lot of factors preventing complete accuracy, but the upside is that a proper colour managed digital print environments are very accurate and more importantly, consistent.

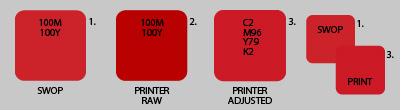

This chart demonstrates how the values for a red are modified to match the red of US Web Coated SWOP v2 using one of our fabric flag ICC profiles.

Remember M100, Y100 is not a colour to match. We can call it red, but we don't know what kind of red, slightly dark, slightly light, slightly orange or slightly blue. On the other hand M100, Y100 in the US Web Coated SWOP v2 colour space is a colour and a specific colour at that, and yes it is a red too. If you want your colours hit more consistently, then always associate an icc to your files. If you don't, we'll use your programmes default's and assume you haven't touched the colour management settings. Although we may not have the right ICC, matching to something is better than matching to nothing.

Corporate colour manuals which use CMYK and RGB formulations should state the colour space they refer to for consistent print to happen.